Leaders in Automated Dispensing Systems, Carousels, Packaging, Pharmacy Robotic Solutions (Inpatient, Retail, LTC & Mail Order), Pharmacy Automation...

Medical Packaging Inc., LLC (MPI), a global healthcare packaging solutions provider for 50 years, provides innovative pharmacy packaging solutions for packaging oral solid and oral liquid medication, and overwrapping and labeling of ampoules, vials and syringes, which contribute to saving patient’s lives by reducing medication errors while also increasing efficiency and automation in pharmacy packaging operations.

MPI’s pharmacy packaging solutions, which include the packaging system, MPI-certified consumable materials and MPI’s exclusive Pak-EDGE™ UD Barcode Labeling Software, have been developed in adherence to industry specifications and meet the requirements of governing regulatory bodies for the repackaging of medication into unit dose. Optional integration to First DataBank drug data, imprints and images library, assists the pharmacy in reducing potential dispensing errors and increasing safety and efficiency.

MPI’s solutions for packaging oral solid medication include the Auto-Print® Standard packaging system, which packages sixty (60) packages per minute (ppm) and the Auto-Print® Express 90 packaging system, which packages ninety (90) packages per minute (ppm). Additional functionality can be achieved through the optional Oral Solid Feeder attachment, which packages bulk medication from the bottle into individual unit dose packages, the Variable Length Option, which allows for adjustment to the package length to accommodate packaging of non-standard sized tablets or capsules, and the Barcode Verifier Option, which automatically scans each package to assure that the printed barcode can be accurately scanned at the bedside.

MPI’s solutions for packaging oral liquid medication include the Fluidose® Series 6 packaging system for packaging medication into unit dose cups and the Auto-Draw® Syringe Filling System for packaging medication into oral syringes.

The Fluidose® Series 6, which packages twenty-two (22) packages per minute (ppm), dependent upon fill rate and viscosity, produces a single, barcoded, unit dose package containing liquid medication to be delivered to the bedside. Fluidose® Series 6 is compliant with The Joint Commission (TJC) regulations for dispensing oral liquid medication and is capable of dispensing volumes between 1 mL and 40mL. Additional functionality can be achieved through the Barcode Verifier Option, which automatically scans each package to assure that the printed barcode can be accurately scanned at the bedside.

The Auto-Draw® Oral Syringe Filling System is a semi-automatic solution that is capable of filling most oral slip syringes up to 50 mL in volume of varying viscosities providing the solution for batch filling of syringes with speed, accuracy and repeatability. Filling operations can be completed in a manner of seconds and no additional software is required. MPI’s Auto-Draw® is ideally used for oral liquid medication doses 1 mL or greater or for those medications that are not typically packaged in unit dose cups or are not commercially available in unit dose.

MPI’s solutions for ancillary packaging include overwrapping and labeling solutions for ampoules, vials and syringes. MPI’s overwrapping solutions include the Pharmacy Accessory Bagging System (PABS), which produces up to thirty-five (35) filled and sealed packages per minute. Labeling and barcoding is done directly on the bag, eliminating costly labels and allowing for customization of the barcode. Bags are available in several different sizes to accommodate even the most irregularly sized items. MPI’s Auto-Print® Max Bagger, packages in bags with a punched hole in the upper half of the package specifically for use with centralized, robotic systems.

MPI’s labeling solutions include the Pharmacy Accessory Label Printer (PALP), which is offered with either direct thermal or thermal transfer technology to quickly and efficiently print accurate barcoded labels for placement on ampoules, vials and syringes. Labels are available in several different styles to accommodate all labeling needs. MPI’s Auto-Wrap® Syringe Labeling System, with labeling and wrapping speed of up to twenty (20) syringes per minute, automates the process of labeling syringes and assists in increasing production throughput while reducing repetitive stress injuries (RSI) by producing a printed label and automatically wrapping it around a syringe in one single motion. The Auto-Wrap® can accommodate any type of oral or injectable syringe from ½ mL to 60 mL without any need for adjustment or changing of parts. Open-faced design allows for easy loading of label stock and access to all controls.

• Visit the Medical Packaging Inc LLC Website

• View the Medical Packaging Inc LLC Platinum Pages Publication Ad

• View the Medical Packaging Inc LLC 20Ways Publication Profile

For more than 40 years, Euclid® Medical Products has been a trusted partner for hospital/retail pharmacies, long-term care facilities and third-party repackagers seeking high-quality, efficient multi/unit dose packaging and barcoding systems.

Euclid® Medical Products is excited to announce the introduction of two new next-generation multi/unit dose strip pouch adherence packaging machines called Axial®.

These next-generation packaging machines are built on a new revolutionary rotary design which allow for a very small footprint (The 144 Canister Machine has a 2’x2’ footprint and the 352 canister machine has a 2’x4’ footprint).

These machines can unit or multi-dose medications and can package at speeds up to 65 packages per minute. Storing up to 15 canisters of one medication for high volume runners, the machines can continue to package as canisters are being refilled.

The new rotary design allows for easy access to the canisters, as well as easy cleaning and maintenance. These machines also have RFID smart canisters and a built-in dehumidifier.

Features:

-2 Models: (144/352 canisters)

-Small footprint: 144 (2'x2') and 352 (2'x4')

-Speeds up to 65 packages per minute

-Can package and replenish canisters at same time

-RFID “Smart Canisters”

-Built-in dehumidifier

-Packaging materials contain technology that provides Fast Easy Opening

-Provides 300 DPI thermal transfer printing and can produce linear and 2D barcodes

Euclid® Medical Products is proud to offer a comprehensive line of oral solid/liquid unit-dose packaging machines (also known as strip packaging machines).

Products Include:

There’s a reason Euclid® Medical Products packaging systems are the most widely used machines in most pharmacies and contract re-packagers. It’s called “The Euclid® Difference”.

• Visit the Euclid Medical Products Website

• View the Euclid Medical Products Platinum Pages Publication Ad

• View the Euclid Medical Products 20Ways Publication Profile

Accu-Chart® has been in the unit dose drug distribution and barcode systems business for over 40 years. Today, we offer a variety of solutions for hospital and pharmacy needs such as unit dose packaging, barcode labeling, blister card filling, medical and surgical supplies and much more.

To learn more, click the link below to visit our website or call (847) 252-7300 to speak to a sales representative today. We look forward to speaking with you!

• Play the Accuchart Informational Video

ARxIUM delivers best-in-class technology and unparalleled expertise focused on helping pharmacies of all sizes and types improve safety, productivity and efficiency. We provide comprehensive and scalable pharmacy solutions for every segment of the pharmacy market – health systems, long-term care, retail, and central fill – designed with category-leading automation hardware and workflow software, and supported by unmatched industry knowledge.

Scalability, efficiency and cost control are the key values of our line of vial-filling solutions designed for community and outpatient pharmacies. Whether you are looking for a sophisticated robotic dispensing device or simply a better way to manage your fast-moving medications, our FastFill™ line can accommodate any script volume.

Featuring

Uses the pharmacy’s available vertical height to increase the number of stock keeping units (SKUs) stored in the same footprint by up to 60 percent. The carousel concept allows technicians to retrieve medications from a single location and the ergonomic design minimizes bending and reaching by picking from waist height.

High volume solutions from ARxIUM are custom-designed for hospital, long-term care, retail and government pharmacies. Our primary high volume solution, OptiFill™ is utilized by more pharmacies than any other system, processing more than 200 million prescriptions each year.

Family-owned mfr of RX LABELS, PILL CARDS, CUSTOM BAGS & RX VIALS, plus the VIVID-1 PILL COUNTER, celebrating 45 years in 2024.

The VIVID Rx is the pill counter you’ve been waiting for. Real-time counting and 99.99% accuracy guarantee you won’t miss a pill. Cost effective and maintenance-free counting is here.

Easily dispense tablets and get instant results. Every count is continuously verifified so that you never second-guess your script.

Large touchscreen display combined with a user-friendly app makes pill counting a breeze. Use it out-of-the-box, with no instructions required. It’s easy to configure and adapt to your pharmacies’ workflow.

No stressful cleaning, disassembly, or database maintenance. Made with premium components and built for the long haul.

HELP WANTED! Are your Ads being answered? Create time, relieve pressure & improve profits by investing in a VISION BASED PILL COUNTER, which have proven to create 10 extra man-hours per week.

Imagine your best CPhT having 40 free hours per month to focus on MedSync, or promote your clinical services. Bi-directional interfaces are available for the leading pharmacy software systems that improve workflow.

With 99.9% accuracy you will virtually eliminate over counts that impact your bottom line, and provide an ROI < 6 months.

Since 1979 Rx Systems has been a part of the community of independent pharmacy, now with locations in five states, and occupying over 250,000 sq ft of manufacturing and warehouse space. Our company was created with the intent of providing a one-stop shop for pharmacy supplies. An emphasis on customer service, while providing quality products at a fair price, has created long term relationships with our business partners.

• Visit the Rx Systems Website

At McKesson Pharmacy Automation, we only partner with the most creative and enterprising engineering firms, best-in-class pharmacy automation manufacturers, and premiere shipping & logistics companies to deliver the best possible experience to our customers and their patients.

You can trust us to provide unparalleled service that is second to none. Our team strives to make every process within your operation safer, more accurate, and as efficient as possible by automating the repetitive and manual tasks that most commonly lead to potential dangers. We are proud to assist our customers with expanding their business while allowing them the time and ability to focus on counseling their patients.

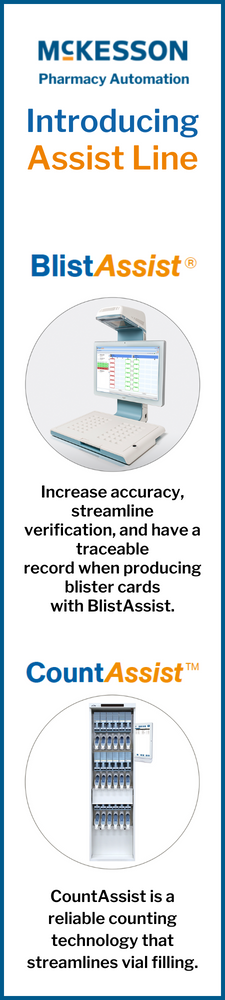

We are proud to present the Assist line, which consists of a counting technology and a blister card technology. These two technologies have in common their efficiency and accuracy when preparing prescriptions.

Part of the counting technology is the CountAssist, a semi-automated machine that is 100% accurate for drug and dose. It holds your top 18 molecules in a single tower but has the flexibility to expand as multiple towers can be daisy-chained together. All cells count individually, directly into their dedicated output chute. This means that multiple cells can count in conjunction, helping to minimize pharmacy wait times during a rush. With its compact design, it can be used as a bay end cap or simply mounted to the wall and only takes up 2 square feet of floor space with no back or side access needed. This technology can truly fit in any dispensary.

Increase accuracy, streamline verification, and have a traceable record when producing blister cards with BlistAssist! BlistAssist connects directly to your pharmacy software, importing multidose blister card production orders into an easy-to-use interface. BlistAssist provides the safety of bottle scanning and light-guided instruction on which cells to place that molecule and in which quantity, ensuring accurate drug and dose every time. Images are taken after every molecule for the verification process. Once complete, remote digital verification can be done from any device that has access to your pharmacy network. The verification images offer an exploded cell view facilitating pill-by-pill verification in an easy-to-use format. These images are then archived for future reference. The average BlistAssist user has seen an increase in production efficiency, a drastic reduction in the number of fill errors (due to bottle scanning & light-guided filling), and an average reduction in verification time of 70%!

• Visit the McKesson Pharmacy Automation Website

• View the McKesson Pharmacy Automation Platinum Pages Publication Ad

• View the McKesson Pharmacy Automation 20Ways Publication Profile

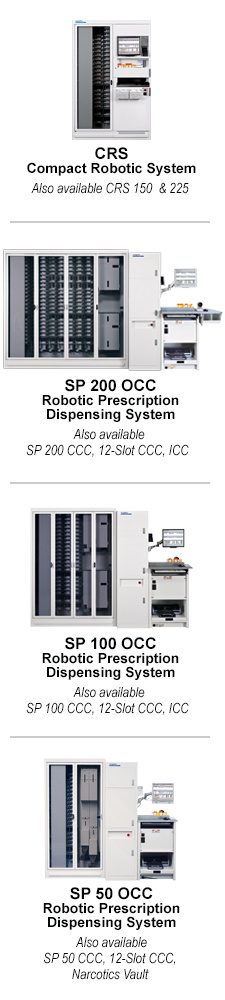

ScriptPro launched the first truly robotic prescription dispensing system in 1994 and it became the gold standard for reliability, longevity, and ROI. That standard holds true today.

From the largest health systems to the smallest retailers, ScriptPro’s Robotic Prescription Dispensing Systems are the proven, time-tested workhorses behind your pharmacy counter.

The Power of ScriptPro Robotics

ScriptPro’s state-of-the-art pharmacy systems get it right with unique advantages that streamline your workflow and operational objectives – backed by dramatically improved safety and accuracy.

• Visit the ScriptPro Automation & Robotics Website

• Play the ScriptPro Automation & Robotics Informational Video

• View the ScriptPro Automation & Robotics Platinum Pages Publication Ad

• View the ScriptPro Automation & Robotics 20Ways Publication Profile

• Print the ScriptPro Automation & Robotics Booth Information

Noritsu understands the challenges you face with large, ever-changing formularies, shrinking reimbursements, and maintaining skilled labor. We recognize that there is no one-size-fits-all solution. That's why we tailor our solutions to meet the unique needs of each pharmacy. By working closely with you and your team, we create integrated packaging systems designed to achieve your specific business goals.

Noritsu’s LittleBot Series is a new line of compact, scalable blister card packagers.

Designed to fit into any pharmacy, the LittleBots bring ease of use, accuracy, and efficiency to your packaging workflow. Whether your employees are new or experienced, the LittleBots help them maintain consistent productivity and accuracy.

The LittleBots line consists of three innovative robots:

The Impact Series machines are built for high-production LTC pharmacies or retail pharmacies that have established LTC services.

Our accurate, fast, and reliable NX Series packagers feature a unique design engineered around efficient pharmacy workflow. The space-saving vertical drawer design allows for more medications in a smaller space, with easy refilling and stock rotation, while the patented "Intelligent Feeder" system ensures the highest level of accuracy.

You don’t need to be an engineer to appreciate the build quality of this equipment. Once you see, hear, and feel how smoothly the NX Series operates, you’ll be confident in its reliability. Reliable equipment means you can spend more time building your business.

The NV series of verification systems offer state-of-the-art medication validation through patient-regimented pouch and dose analysis. Built with durability and accuracy in mind, an NV system can dramatically increase your packaging throughput by quickly checking every pouch for accuracy.

At the heart of all our systems lies the NexusRx pharmacy control software suite. Combining pharmacy management, packaging, verification, and archiving into one efficient and versatile workflow, Noritsu NexusRx software lets you take control of your entire backroom operation. Whether it's having complete control over your orders prior to packaging, printing labels, or analyzing your packaging data, NexusRx provides the tools to manage and improve your day-to-day pharmacy operations while offering your customers more options and versatility.

Pharmacy Advantages

Facility Advantages

• Visit the Noritsu Pharmacy Automation Website

• View the Noritsu Pharmacy Automation Platinum Pages Publication Ad

• View the Noritsu Pharmacy Automation 20Ways Publication Profile

The DRX-500s Cloud is Torbal’s newest, top of the line pill counting scale. The scale mixes speed, accuracy, and an all-around ruggedness to provide a terrific return on investment in just weeks. Our pill counter connects to a Cloud Server via the internet where it transmits information back and forth during transactions. The server is preloaded with over 3,000 drug piece weights and provides access to the entire NDC drug database.

In addition, the cloud server provides its supervisors with an intuitive administrative panel to monitor all activity amongst the connected scales. The panel provides access to login permissions, transaction details, user activity, and email reporting & alerts for miscounts. The cloud server can be shared amongst all of the users, minimalizing updating responsibilities, or a private database can be configured specifically for you. The best part is the DRX-500s Cloud requires no setup, simply just plug and play!

Features:

Counts 100 Tablets in Less Than 20 Seconds

A typical pill counting transaction of 60 pills, performed on a DRX500 scale connected to the TORBAL server is made in three easy steps, and can be performed under 20 seconds. The steps are simple: tare the vial, scan the NDC located on the supply bottle, and fill the count. During each count the scale displays the name of the drug and other important drug information.

Advanced Pill Counting Accuracy

APA is an advanced pill counting algorithm that quickly and efficiently adjusts for pill weight variations providing even greater accuracy when filling prescriptions. The feature is very easy to use and requires little user interaction. This system not only improves counting accuracy, it also speeds up the process significantly and eliminates the need for the pharmacist to count pills manually when updating average piece weights.

Interactive Administration Panel

The software is easily accessed and viewed with the use of a web browser such as Internet Explorer or Mozilla Firefox. Once logged-in, the administrators have access to detailed graphs, charts, and reports, of performed transactions. The admin panel is also used to setup users and configure the server. Each server offers great flexibility and can be configured to fit particular pharmacies needs and requirements.

Automatic Email Reporting and Alerts

The TORBAL server generates and automatically emails daily, weekly, monthly, and quarterly reports which include details about performed counting transactions, verifications, most frequently counting drugs, as well as detailed user activity. When using features such as prescription size or Rx verification, the TORBAL server monitors and records pill counting transactions to make sure that verification was performed successfully and that the count was filled accurately. If a user causes a miscount, by filling too many or not enough pills as required, or if a user fails Rx verification, the server instantly sends out an email alert to all administrators with a notification.

Rx NDC Verification

The NDC verification feature eliminates potential errors in prescription filling. It ensures that a prescription is correctly counted and filled. The feature allows the user to compare two NDC codes and check for a match. The NDC on your Rx label barcode is compared to the stock bottle barcode. If the two scanned NDC codes are the same the scale displays "Match OK" and allows you to proceed with pill counting. If the codes are different, the scale displays a "Failed" message. Pill counting transactions which have failed Rx verification are recorded by the server in a dedicated report. As soon as "Failed" Rx verification occurs the server instantly sends out an email alert notifying the administrators.

• Visit the Scientific Industries Inc Website

• View the Scientific Industries Inc Platinum Pages Publication Ad

• View the Scientific Industries Inc 20Ways Publication Profile

20 Ways Profile Generic Account

Thirty Madison chose Tension, a leader in packaging equipment and automation systems for the e-commerce and pharmacy industries...

Noritsu Pharmacy Automation

As a long-term care pharmacy, Neil Medical functions as a distribution warehouse, while also focusing on successful patient outcomes...

Swisslog

Streamlined Pharmacy Operations with the BoxPicker Automated Pharmacy Storage System to Drive Efficient Medication Management...

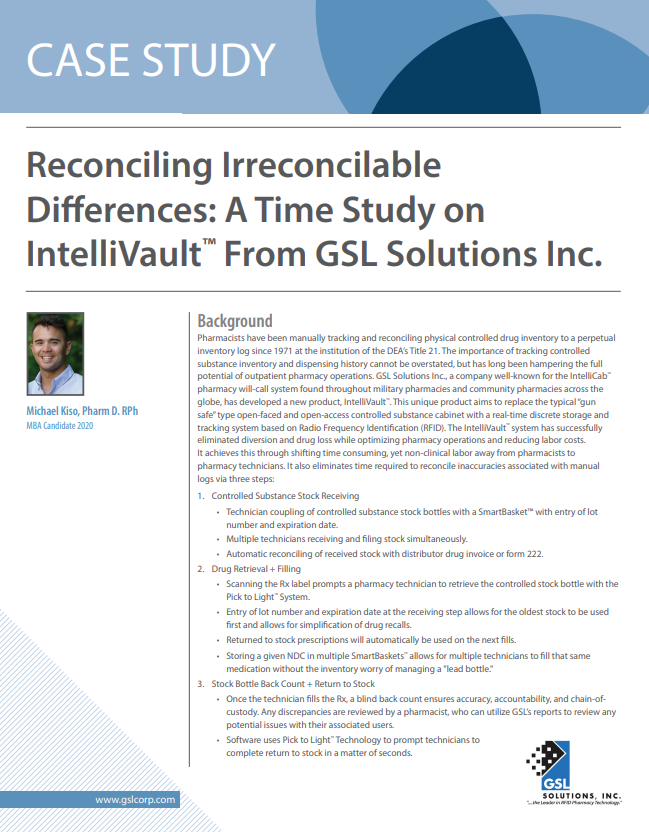

GSL Solutions

An updated timestudy on Intellivault from GSL Solutions, Inc...

GSL Solutions

RFID-based technology from GSL Solutions delivers safety, efficiency, and financial benefits at health system...

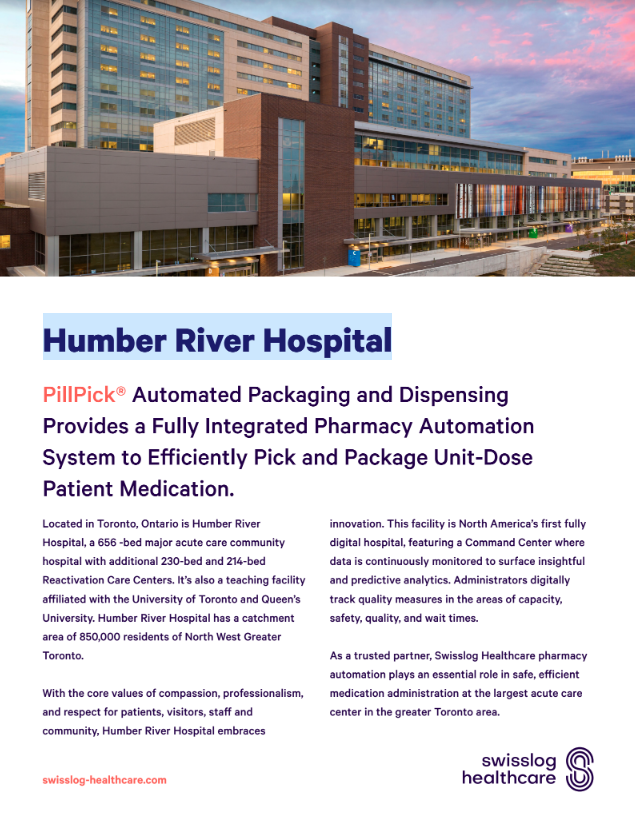

Swisslog

PillPick Automated Packaging and Dispensing Provides a Fully Integrated Pharmacy Automation System to Efficiently Pick and Package Unit-Dose Patient Medication...

Noritsu Pharmacy Automation

Offering the latest in pharmacy automation technology, including strip pouch packaging systems that reduce labor and boost efficiency...

GSL Solutions

Safety, Accountability, Efficiency and Compliance. See what others have already discovered...

RxSafe

Southern Pharmacy uses the Parata Max in combination with the RapidPakRx...

Parata

Maintaining a large inventory without sacrificing safety and efficiency...

McKesson Pharmacy Systems

Managing patients and their clinical needs while achieving important pharmacy goals is possible with a single, powerful software solution...

Connect with thousands of pharmacy professionals throughout every practice setting.

The server is experiencing a problem at this time. Try again later.